| Our Products |

| |

- Activated Alumina

VJIKKS ENGG POWER (M) SDN BHD representing Devson Catalyst Pvt Ltd in Malaysia supplies Activated Alumina. Devson is the one of the largest manufacturers of Activated Alumina in India with capacity of 3600 MT per year. Devson is having most modern manufacturing facility and advance technology of spin flash calcinations of alumina which calcine each and every molecule of alumina resulting the high quality properties such as Adsorption, Surface area, Pore Volume and Mechanical strength with low attrition loss. Devson Activated Alumina is designed to give a dew point of at least -40°C in most conditions.

Applications

- Purification of gases and liquids (removal of metallic trace, TBC and HF compounds)

- Drying of organic liquids such as LPG, propylene, butane, steam cracked liquids, cyclohexane, gasoline and fluoro hydrocarbons, aromatic solvents

- Drying of air and gases such as steam cracked gases, catalytic reforming recycle gas, synthesis gas, natural gas, CO2

- Drying of air and gases as steam cracked gases, catalytic reforming recycle gases, synthesis gases, methyl chloride, natural gas, LNG, etc.

- Drying of hydrogen, oxygen, nitrogen, CO2, etc.

- Purification of gases and liquids (removal of metallic traces, BF#, TBC, HCI, HF and fluorinated hydrocarbons)

- Catalyst for Claus conversion in sub dew point processes

- Air drying (PSA, TSA)

- Instrument air, supersonic wind tunnel, compressed air

- Gas drying Air separation plants, inert and rare gases, hydrogen, oxygen, nitrogen, CO2

- Natural gas in production and compression plants, LPG, LNG

We offer different packing method for our Activated Alumina DEV-101™ like 20 kg bag packing, 200 Liter Drum Packing and Jumbo Bag Packing.

Sulfur Recovery Catalyst (Claus Catalyst)

Devson has the most extensive line of Claus Catalyst in the industry. In addition to non- promoted and promoted activated alumina, we also offer sulfur Recovery Catalyst, DEV-SR™. Devson Sulfur Recovery is Alumina Based.

What is a Claus Catalyst?

Sulfur Recovery Units (SRU) converts unwanted hydrogen sulfur (H2S) and sulfur dioxide (SO2)to the desired element, sulfur. This is done most often using the Claus process. SRUs are essential parts of refineries, smelters and natural gas plants, where large amounts of H2S are produced. The quality of the Claus Catalyst is critical for maximizing the performance of the SRU. Devson extensive product line of Claus Catalysts provides the superior value that is needed.

Why Devson Claus Catalyst?

Devson offers a full range of Claus Catalysts with a large number of accessible surface active sites for H2S and S2O to react and form sulfur and water (high surface area), large pore volume distribution (high macro porosity), low bulk density which directly lowers catalyst expense, low abrasion and high strength which minimizes dust and fines and uniform size and shape for lower pressure drops.

We offer different packing method for our Sulfur Recovery Catalyst DEV-SR™ like 20 kg Bag Packing, 200 Liter Drum Packing and Jumbo Bag Packing.

Chloride Guard Catalyst

The presence of chloride in refinery streams typically has two sources : crude oil and the catalytic reforming unit. While less common, certain crude oil assays do contain species of organic chlorides that are not removed in the desalter. The most common source of chloride, however, is the catalytic reforming unit. These units utilize metal and acid functionality, with chloride injected and adsorbed onto the catalyst to provide the acid function necessary for optimal conversion and selectivity.

This chloride is not permanently bound to the support and is therefore sent put with all product streams. Effects of chloride in downstream operations can be :

- Corrosion of austenitic stainless steels

- Ammonium chloride salting – corrosion and pressure drop issues

- Corrosion of downstream piping/equipment

A fixed bed of DEV-CG™ chloride absorbent is the best solution for this problem.

Performance is key when it comes to chloride guard materials. Poor materials will result in the formation of debilitating factors such as the formation of organic chlorides or green oils. These will result in premature outages of very expensive pieces of equipment and deration of valuable refinery processes. DEV-CG™ materials have been formulated to provide the best protection against these undesired products, giving the user peace of mind that they are doing the most that they can to maximize profitability and reliability within their plant.

Tower Packing

Devson Catalyst Private Limited is leading manufacturer of Ceramic Tower Packing. Support for use in various refining, Chemical, Petro-chemical, gas processing, Fertilizer and environmental industries. With more than 15 years of experience in ceramics, today Devson manufactures international standard quality products with the help of their engineers and ceramist.

Devson is having range of full Tower packing which includes saddles, Raschig Rings, Pall Rings and Partition Rings.

Devson Tower Packing is having excellent Chemical Resistance along with great mechanical strength which gives better mass transfer efficiency with low pressure drop.

Application

Devson Tower Packing are widely used in Distillation column Towers, Absorption Tower, Stripping Towers, Scrubbers etc. in Petro-Chemical industry, chemical Industry, Fertilizer Industry, Refineries, Natural Gas Industries and Environmental protection industry.

Advantages

- Excellent Liquid distribution

- Low Pressure drop

- High Mechanical Strength

- Higher Resistance to Chemicals and Corrosive Agents

- Greater Contact Area

- High Random Orientation

In a nutshell our products and solutions are First World Products and Solutions at Third World Price.

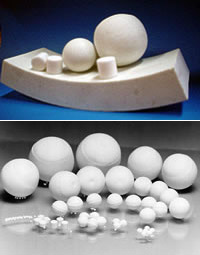

- Inert Ceramic Balls

VJIKKS ENGG POWER (M) SDN BHD representing Devson Catalyst Pvt Ltd in Malaysia supplies Inert Ceramic Balls of excellent quality. Devson make inert ceramic balls are having low water absorption, 100% survival in rapid depressurization test, high crushing strength, better impact Resistance (drop test), thermal shock resistance (quench test), very low attrition loss. Today, Devson make inert ceramic balls are widely used in petroleum refining, petrochemicals, fertilizers plant, acid Plants and industrial gas industries.

Application of Inert Ceramic Ball & Alumina Balls

Refinery Industries:

- Hydro cracking

- Hydro treating

- Hydrogenation

- Reforming

- Isomerization

Fertilizers & Ammonia Plants:

- Desulturizers

- Hydro treating

- Methanator

- Secondary Reformers

- High Temp. Shift

|

Petrochemicals:

- Hydrogenation

- Hydro treating

- Oxidation

- Absorbers

- Desulfurizers

- Molecular Sieve support

- Separation Ethylene Creaking & Drying

- Polymerization

Acid Plants:

|

Natural Gas Processing :

- Dryers

- LNG Prepurifiers

- LPG Treaters

- Claus Realtors

Industrial Gases:

|

Devson Manufacture 3 types of ceramic balls with size from 2mm to 50mm.

DEV-25™, DEV-50™ and DEV-99™ are low purity, medium purity and High Alumina balls respectively.

In a nutshell our products and solutions are First World Products and Solutions at Third World Price.

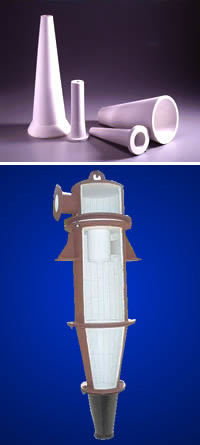

- GAS CHLORINATOR ACCESSORIES

Auxiliary Container Valve

Auxiliary Container Valve

This is an additional valve assembly to be mounted on the existing container valve. This assembly is mounted with the help of a yoke. The auxiliary container valve eliminates the possibility of leakage from the damaged container valve & the chance of gas or liquid chlorine back flowing during changing of the container. The yoke is very sturdy in construction and offers positive fixing of the auxiliary container valve or flexible copper connector with the chlorine container.

Flexible Copper Connector

The flexible copper connector is used with Cylinder, Tonner, Header and Chlorinator to form the required connection. This connector comes with a standard length of 1.5 Mtrs. with end fittings suitable for ton container valve. The silver brazing of end connectors offer a long corrosion Free service.

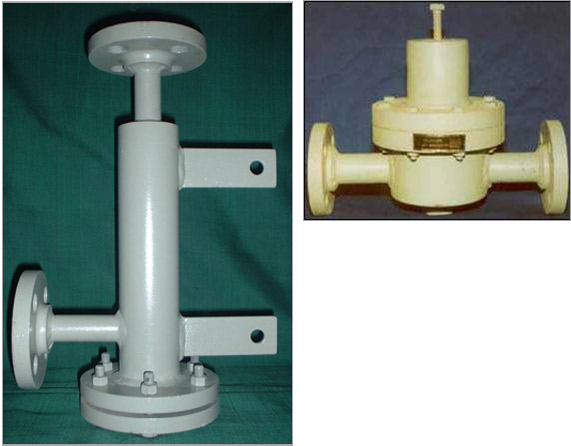

Pressure Reducing Valve

The container pressure of chlorine varies between 8 to 10 kg/cm2, which is very high to either meter or doze accurately. Hence a pressure-reducing valve is used in the system. This valve is capable of reducing the pressure of chlorine to manageable limit of approximately 2 kg/cm2. The pressure-regulating valve is spring loaded with PTFE diaphragm. This valve prevents the re liquification in the system.

Chlorine Gas Filter

Chlorine gas filter mounted in the Chlorine gas line is one of the very important components in the Gas Chlorination system helps to eliminate the carry over of Ferric Chloride and other impurities in the system.

Product Range & Capacities

Cylinder Mounted Chlorinator: 0.25,0.5,1,2,3,4,5,6,8,10 kgs/hr

Wall Mounted Chlorinator: 0.25,0.5,1,2,3,4,5,6,8,10 kgs/hr

Floor Mounted Chlorinator : 0.25kg/hr to 200kgs/hr

In a nutshell our Gas Chlorinators are First World Products at Third World Price

In a nutshell our Gas Chlorinators are First World Products at Third World Price

- FLOOR AND WALL AND CYLINDER OR TONNER MOUNTED GAS CHLORINATORS

Design and construction:

Design and construction:

Our Floor and Wall mounted Chlorinators are vacuum operated, solution feed type. It is designed for floor mounting or wall mounting and incorporates a filter, flush mounted chlorine pressure gauge, a reliable vacuum regulator, and an accurate flow-meter, a precise flow control valve, and effective differential regulator, an injector, and a positive non-return valve. All the components are mounted in a two-tone, gel coated attractive fiber glass cabinet.

The vacuum regulator is of an exclusive design, which opens only when the vacuum is generated by the injector. On failure of water supply to the injector, the vacuum regulator closes automatically. DP (Differential Pressure) Regulators are provided only in capacities of 10 kgs/hr and above.

The material of construction used for the various components of our Chlorinators are of highly resistant to chlorine, like PVC, HDPE, Teflon (PTFE), Monel and fiber glass.

Our cylinder mounted chlorinators are sturdy and easy to operate and maintain. The Chlorinator can be mounted on a 65/100 kg cylinder or on a 1000 kg tonner. The mounting arrangements are different for cylinders and tonners. The injector and check valve assembly will be mounted separately near the dozing point. The interconnecting flexible pre tube is supplied as per requirements.

The simple and yet advanced design of the various components reduce the maintenance of the chlorinators to a bare minimum. All the components are easily accessible from the rear of the cabinet for periodic Inspection and Maintenance.

Our Chlorinators are pre-assembled and is fully tested under simulated operating condition. This saves time and money during installation and helps towards a smooth start-up.

Operating Principle:

Water passes through the injector to produce vacuum. This vacuum opens the check valve and passes through the DP regulator and extends up to the vacuum regulator.

The chlorine gas under pressure from the container passes through a filter, where ferric chloride impurities are removed. The chlorine gas under pressure is converted into a constant vacuum at the vacuum regulator. The chlorine gas under vacuum passes through the flow meter, flow control valve and differential regulator before getting mixed with the water in the injector where it forms a chlorine solution. The chlorine solution is then discharged at the dosing point.

Product Range & Capacities

Cylinder Mounted Chlorinator: 0.25,0.5,1,2,3,4,5,6,8,10 kgs/hr

Wall Mounted Chlorinator: 0.25,0.5,1,2,3,4,5,6,8,10 kgs/hr

Floor Mounted Chlorinator : 0.25kg/hr to 200kgs/hr

In a nutshell our Gas Chlorinators are First World Products at Third World Price

In a nutshell our Gas Chlorinators are First World Products at Third World Price

- CHLORINE VAPORIZER

Vaporizers are recommended for higher continuous chlorine gas feed rates, when it is not practical to use manifolds for the gas lines of the required number of containers. By withdrawing the chlorine as a liquid and using vaporizer, flow rates can be greatly increased.

Electrically Heated Vaporizer

Liquid chlorine from the pressurised tonner flows to the inner chamber of the vaporizer. This chamber is immersed in a water bath, which is heated by 3 Nos. heaters. The water to the water bath is supplied via pipe which is controlled by a solenoid operated valve, which opens once the water level falls below the preset level and closes once the water reaches the higher preset level. The temperature of the water is controlled by a thermostat, which switches ON or OFF depending upon the temperature of the water bath. To protect the Heat Exchanger and Hot water tank surface exposed to water, from Galvanic Corrosion, Cathodic protection is provided by means of sacrificial carbon anodes.

Steam Heated Vaporizer

Chlorine Vaporizer can also be powered by steam. Steam is abundantly available in Paper & Pulp Mills, where steam is used to evaporate liquid Chlorine to form gas Chlorine. A temperature controller opens or closes a steam valve, thus maintaining a constant temperature in the steam chamber.

Product Range & Capacities

Cylinder Mounted Chlorinator: 0.25,0.5,1,2,3,4,5,6,8,10 kgs/hr

Wall Mounted Chlorinator: 0.25,0.5,1,2,3,4,5,6,8,10 kgs/hr

Floor Mounted Chlorinator : 0.25kg/hr to 200kgs/hr

In a nutshell our Gas Chlorinators are First World Products at Third World Price

- CHLORINE LEAK ABSORPTION SYSTEM

This system is essential wherever chlorine is handled and used in large quantities. The chlorine leak absorption system is highly useful when chlorine leaks from the tonner valves due to total break down of chlorine valve or any puncture on the wall of the tonner.

The system designed and supplied by us consist of gas chamber, blower, absorption tower, alkali tank and recirculating pump with all the required ducting piping and fittings. The system is designed to absorb a total leakage of 1,000 Kgs or more of chlorine leak. The system can be offered with complete room evacuation or spot evacuation in and around the tonner area.

Chlorine Leak Detector

The Chlorine gas detection system consists of a control unit and a sensor. The Sensor mounted remotely senses the gas present in the room, which is indicated on the panel. Apart from the audio visual alarm present in the panel, there is a potential free contact which can be used to trigger a remote alarm or actuate the exhaust fan.

Product Range & Capacities

Cylinder Mounted Chlorinator: 0.25,0.5,1,2,3,4,5,6,8,10 kgs/hr

Wall Mounted Chlorinator: 0.25,0.5,1,2,3,4,5,6,8,10 kgs/hr

Floor Mounted Chlorinator : 0.25kg/hr to 200kgs/hr

In a nutshell our Gas Chlorinators are First World Products at Third World Price

In a nutshell our Gas Chlorinators are First World Products at Third World Price

- AUTO CHANGEOVER FOR GAS CHLORINATORS

Whenever and wherever continuous and uninterrupted Chlorine gas supply is required then an Auto Change Over System is used.An Auto Change Over can be accomplished either by a Vacuum Auto Changeover or Electrical Auto Changeover

Vacuum Auto Changeover

Whenever and wherever continuous and uninterrupted Chlorine gas supply is required then an Auto Change Over System is used.An Auto Change Over can be accomplished either by a Vacuum Auto Changeover or Electrical Auto Changeover

Vacuum Auto Changeover

Vacuum Auto Changeover Module is provided in Gas Chlorinators, to have continuous gas flow without any interruption. Normally, One Vacuum Regulator is mounted on each one of the two cylinders or Tonners. The outlet pipes from these Vacuum Regulators are connected to either side of the Auto Changeover Module. The outlet from the Auto Changeover Module is connected to Injector through a Rotameter and Flow Control Valve assembly. When the Injector is switched ON, Chlorine from one of the tonners flows through the Auto Changeover Module. Once the operating tonners become empty, then Vacuum is developed inside the Auto Changeover Module and activates the toggle switch assembly which changes over to the other filled tonner.

Electrical Auto Changeover

Electrical Auto Changeover Module is provided in Gas Chlorinators, to have continuous gas flow without any interruption. It consists of Pressure Sensor, Motorized Valve, and Control Panel etc. There are two Manifolds each connected to one or a battery of filled tonners. When the system is started, one manifold will allow the gas to flow out from a tonner. As soon as the working tonner gets empty the pressure switch provided on the gas line will sense 'the no chlorine' condition and it will energise the motorized valve to open the standby manifold. If both Manifold are empty then the Control Panel will give an 'audio visual alarm'. The Valves on the Manifold can also be opened manually, by passing the Auto mode.

Product Range & Capacities

Cylinder Mounted Chlorinator: 0.25,0.5,1,2,3,4,5,6,8,10 kgs/hr

Wall Mounted Chlorinator: 0.25,0.5,1,2,3,4,5,6,8,10 kgs/hr

Floor Mounted Chlorinator : 0.25kg/hr to 200kgs/hr

In a nutshell our Gas Chlorinators are First World Products at Third World Price

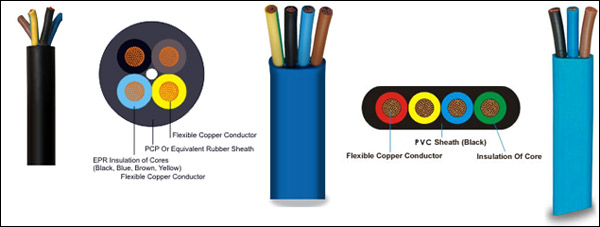

- SUBMERSIBLE PUMP CABLES

We, VJIKKS ENGG POWER (M) SDN BHD ,progressing aggressively as a One Stop Engineering Solution Company, supply Submersible Pump Cables from a No. 1 Manufacturer of PVC/Rubber Insulated flexible Copper Cables in INDIA and exporting around the world with 40 years of continued experiments and innovations in this field make the cables an unmatched quality product compared to any international manufacturer.

Our manufacturer is a primary O.E.M Cable supplier for all leading Indian Submersible Pump Brands without any notable competitions.

Our manufacturer is an ISO 9001 : 2008 Certified manufacturer by BVQI for Quality Management System and the products are CE marked.

For your Water Pump / Dewatering Pump / Water Project / Drinking Water Plant / Mine Dewatering /Drilling Rigs (off/on shore) applications our Flexible Copper Cable with PVC/Rubber Sheath Multi core/Single core are available in International Standard as well as Customize requirement.

Submersible pump cables of sizes as below:

PVC 3 Core Flat Cables

PVC 4 Core Flat Cables

PVC 3 Core Round Cables

PVC 4 Core Round Cables

Rubber 3 Core Flat Cables

Rubber 4 Core Flat Cables

Rubber 3 Core Round Cables

Rubber 4 Core Round Cables

DRINCABLE

H07RN-F CABLES

AWG Pump Cables

PVC Copper Cables

PVC Copper Cables are made from Virgin PVC manufactured in their own PVC Beans producing plant, to provide best quality products.

Rubber Copper Cable are made from Best Quality Rubber. EPR/NBR Range is also available.

Drin Cable Lead-Free Cables for Drinking Water Plant / Municipal Drinking Water Supply Project, Water Tank.

Customize Cable as per Customer/Project/OEM product require customize requirement can serve.

In a nutshell Our products are First World Products at Third World Price

- PLATE HEAT EXCHANGER

Indirect heat exchanger, where both media are separated by a wall through which heat is transferred.

Indirect heat exchangers are available in several main types: Plate ,Shell, Tube, Spiral etc.

In most cases the plate type is the most efficient heat exchanger.

We supply Plate Heat Exchangers from a reputable manufacturer.

Generally it offers the best solution to thermal problems, giving the widest pressure and temperature limits within the constraint of current equipment

With a plate type heat exchanger, the heat penetrates the surface, which separates the hot medium from the cold one very easily. It is therefore possible to heat or cool fluids or gases which have minimal energy levels.

One of the very efficient heat exchangers is the plate heat exchanger. It is composed of multiple, thin, slightly-separated plates that have very large surface areas and fluid flow passages for heat transfer. This stacked-plate arrangement can be more effective, in a given space, than the shell and tube heat exchanger. Advances in gasket and brazing technology have made the plate type heat exchanger increasingly practical. In HVAC applications, large heat exchangers of this type are called plate-and-frame; when used in open loops, these heat exchangers are normally of the gasketed type to allow periodic disassembly, cleaning, and inspection.

There are many types of permanently-bonded plate heat exchangers such as dip-brazed and vacuum-brazed plate varieties, and they are often specified for closed-loop applications such as refrigeration. Plate heat exchangers also differ in the types of plates that are used, and the configurations of those plates. Some plates may be stamped with "chevron" or other patterns, where others may have machined fins and/or grooves The most notable advantages of a plate heat exchanger are:

Thin material for the heat transfer surface - this gives optimum heat transfer, since the heat only has to penetrate thin material.  High turbulence in the medium

High turbulence in the medium –this gives a higher convection, which results in efficient heat transfer between the media.

The high turbulence also gives a self cleaning effect. Therefore, when compared to the traditional shell and tube heat exchanger, the fouling of the heat transfer surfaces is considerably reduced. This means that the plate heat exchanger can remain in service far longer between cleaning intervals.

Flexibility - the plate heat exchanger consists of a framework containing several heat transfer plates. It can easily be extended to increase capacity.

Furthermore, it is easy to open for the purpose of cleaning. (This only applies to gasketed heat exchangers, and not to brazed units.)

Variable thermal length - most of the plate heat exchangers manufactured by us are available with two different pressing patterns. When the plate has a narrow pattern, the pressure drop is higher and the heat exchanger is more effective. When the plate has a wide pattern, the pressure drop is smaller and the heat transfer coefficient is accordingly somewhat smaller.

We can design, manufacture, supply, install, test and commission Plate Heat Exchangers made out of SS and Titanium.

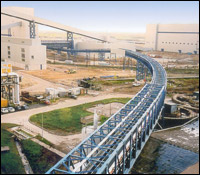

- CONVEYOR BELTS FOR WOOD INDUSTRIES

We, VJIKKS ENGG POWER (M) SDN BHD ,progressing aggressively as a One Stop Engineering Solution Company, supply Conveyor Belts from a No. 1 Manufacturer of Conveyor Belts in INDIA and exporting around the world.

Conveyor Belts are manufactured for various industrial applications

- General Purpose Belt

- Heat Resistant Belts

- Oil Resistant Belts

- Chemical Resistant Belts

- Pipe Conveyor Belts

- Fire Resistant Belts

The conveyor belts manufactured are up to 2000 mm width and in various grades conforming to international standards.

Conveyor belts particularly suited to Wood related industries, for various applications from conveying light weight wood chips to the heavy belt that withstands the impact of tree logs.

Common Widths : 500 mm to 2000 mm

Carcass Variety Available : EP / NN

Common Belt Rating : 400 KN/M

No. of Plies : 3 ply or 4 ply

Rubber Cover Grades : Soft Wear Resistant Cover

Rubber Covers Thickness : Top cover between 5 to 10 mm, Bottom cover

either Bare back or Slider Back

Rubber : Non marking, Green , Pinkish Red

Surface Finish : Smooth both sides or Large Diamond Profile

Edge : Cut Edge

Splicing Method : Hot splice joint / Mechanical splice

Packing Available in : Single Roll

SLOWDOWN BELTS:

This belt has been designed to slow down Log deck movement by absorbing high speed of logs coming out of sizing machines and to simultaneously change the direction of the log. These Belts are made with a unique, soft wear resistant cover with non marking and high traction properties. We offer these belts with bare back plies for easy sliding on metal surface. For providing higher traction, we also supply this belt with a proprietory, special moulded profile for heavier duty applications.

TIMBER CONVEYOR BELTS:

These belts are light weight, supple, 3 ply belts designed to work with small diameter pulleys. These belts have a bare back construction. Cover grades have excellent oil and weather resistant properties, to prevent oil swelling associated with carrying wood / chips with content of Pine sap or Terpene oil. These belts are supplied in non marking compounds or in black covers, depending on client preference.

WOOD CHIP PROFILE BELTS:

These belts have studs on the surface to prevent slide back of wood chips, barks on high inclined conveyors. Belts are normally 3 ply - 4 ply construction, having either bare back or having bottom covers. These belts are moderately oil resistant and black in colour.

IN A NUTSHELL OUR PRODUCTS ARE FIRST WORLD PRODUCTS AT THIRD WORLD PRICE

- CONVEYOR BELTS FOR POWER PLANTS

We, VJIKKS ENGG POWER (M) SDN BHD ,progressing aggressively as a One Stop Engineering Solution Company, supply Conveyor Belts from a No. 1 Manufacturer of Conveyor Belts in INDIA and exporting around the world.

Conveyor Belts are manufactured for various industrial applications

- General Purpose Belt

- Heat Resistant Belts

- Oil Resistant Belts

- Chemical Resistant Belts

- Pipe Conveyor Belts

- Fire Resistant Belts

The conveyor belts manufactured are up to 2000 mm width and in various grades conforming to international standards.

In Coal Fired Power Plants ,one of the main hazards to which a conveyor system is prone to is Fire. Since general purpose conveyor belts are combustible, in certain areas which are exposed to fire risk, we recommend the use of fire resistant belts. The effect of a fire entails a safety hazard for the personnel as well as potential financial loss caused due to damage to the installation and of course substantial production loss which follows any such breakdown.

With the advancement in technology, it is possible to impart properties to conveyor belts so that in fact the propagation of the fire is arrested or limited at the source. This is done by using a combination of polymers, chemicals and additives which contribute to improving the fire retardant property of the conveyor belt.

This can often be achieved without compromising the wear life of the conveyor belt as well.

In order to cater to varying levels of fire resistance in line with various domestic and international standards, we supply a range of fire resistant belts . This range includes belts suited for underground use and specialized belts with low smoke and toxicity.

Belts with added feature of Heat and /or Oil Resistant property are also available on request.

Common Widths : 500 mm to 2000 mm

Carcass Variety Available : EP / NN / PP

Common Belt Rating : 200 to 2500 KN/M

No. of Plies : 2 ply to 6 ply

Rubber Cover Grades : Refer table

Rubber Covers Thickness : Minimum 1.0 mm to 20 mm

Rubber : Black

Surface Finish : Smooth

Edge : Cut Edge or Molded Edge

Splicing Method : Hot splice joint / Mechanical splice

Packing Available in : Cassette / Single Roll

Belt Identification : Unique Product identification Number (PIN) at every 10m

IN A NUTSHELL OUR PRODUCTS ARE FIRST WORLD PRODUCTS AT THIRD WORLD PRICE

- CONVEYOR BELTS FOR PACKING INDUSTRIES

We, VJIKKS ENGG POWER (M) SDN BHD ,progressing aggressively as a One Stop Engineering Solution Company, supply Conveyor Belts from a No. 1 Manufacturer of Conveyor Belts in INDIA and exporting around the world.

Conveyor Belts are manufactured for various industrial applications

- General Purpose Belt

- Heat Resistant Belts

- Oil Resistant Belts

- Chemical Resistant Belts

- Pipe Conveyor Belts

- Fire Resistant Belts

The conveyor belts manufactured are up to 2000 mm width and in various grades conforming to international standards.

To suit to the needs of Packing Industries, belt is specially designed for transporting light weight goods, either in inclined or in horizontal planes. These belts are designed to transport either fragile material or packed goods, such as, glass, papers, bags, boxes or cartons etc.

The deep impression top cover on the belt provides thousands of flexible gripping; these gripping generate the relief effect, absorbing any vibrations and impacts exerted on the materials and

simultaneously prevents the material from slipping on high inclined conveyors.

The belts are light in weight, move on either slider bed or on idler rollers. For slider beds, we manufacture these belts with our special bare back fabric construction. Special care is taken to ensure that there is no “strike through�� of rubber on the bare side.

These belts are suitable for Packing industry, bagging plants , Food packaging industry ,Fragile goods manufacturing / packing industries.

However our belts are not suitable for conveying goods where the angle of incline is more than 35 degrees. Also conveying of sticky material and powder is not recommended.

Characteristics of the belt

Width : Up to 1500 mm

Ply : 2 plies to 3 plies

Belt Length Range : Standard Length of 100 m

Carcass Variety Available : EP / NN

Carcass Strength Rating : 200 - 500

Rubber Cover Grades : M / N / DIN Y

Rubber Covers Thickness : min. 3.0 mm top cover, 1.5 mm bottom cover

Rubber : Black

Surface Finish : Top rough Top and Bottom with cover or Bare back

Edge : Cut Edge only

Splicing Method : Hot splice / Cold splice / Lacing

Packing Available : Single Roll

IN A NUTSHELL OUR PRODUCTS ARE FIRST WORLD PRODUCTS AT THIRD WORLD PRICE

- CONVEYOR BELTS FOR HEAVY DUTY

We, VJIKKS ENGG POWER (M) SDN BHD ,progressing aggressively as a One Stop Engineering Solution Company, supply Conveyor Belts from a No. 1 Manufacturer of Conveyor Belts in INDIA and exporting around the world.

Conveyor Belts are manufactured for various industrial applications

- General Purpose Belt

- Heat Resistant Belts

- Oil Resistant Belts

- Chemical Resistant Belts

- Pipe Conveyor Belts

- Fire Resistant Belts

The conveyor belts manufactured are up to 2000 mm width and in various grades conforming to international standards.

Steelflex belts are manufactured with a high tensile, heavy duty woven steel fabric using the proprietary Fleximat fabric. M/s Bekaert, Belgium, are the pioneers in the design and development of

Fleximat fabric. MAXX Steelflex is designed to perform in the following applications:

- High tension conveyors

- Long haul conveyors

- Short, high speed feeder belts prone to rip and tear due to tramp material

- Heat resistant belts prone to “burn through��

- Heavyduty elevator belts MAXX Steelflex belts offer the following benefits:

- Conventional Steel cord belts do not offer longitudinal rip resistance

- Lower break down costs since rip length is restricted by weft fabric

- Suitable for smaller pulley diameters as compared to Steel Cord belts

- Low elongation @ ref.load of 0.3% v/s 2.0%

- Substitute for steel cord belts

Ratings : 350 N/mm to 3150 N/ mm

Top Covers : 5mm and above

Bottom Covers : 3mm and above

Common Widths : upto 2000mm max

Edge : Molded Edge only

Splicing Method : Finger Splice as per Oriental’s advice

Belt Identification : Unique Production Identification

Number (PIN) at every 10m

IN A NUTSHELL OUR PRODUCTS ARE FIRST WORLD PRODUCTS AT THIRD WORLD PRICE

- CONVEYOR BELTS FOR CEMENT INDUSTRIES

We, VJIKKS ENGG POWER (M) SDN BHD ,progressing aggressively as a One Stop Engineering Solution Company, supply Conveyor Belts from a No. 1 Manufacturer of Conveyor Belts in INDIA and exporting around the world.

Conveyor Belts are manufactured for various industrial applications

- General Purpose Belt

- Heat Resistant Belts

- Oil Resistant Belts

- Chemical Resistant Belts

- Pipe Conveyor Belts

- Fire Resistant Belts

The conveyor belts manufactured are up to 2000 mm width and in various grades conforming to international standards.

Conveyor belts particularly suited to Cement industries, where conveyor systems having inclined angles greater than 18 degrees, the material tends to roll back. To counter this, the conventional approach is to increase the speed of the conveyors. But, this approach will result in increased energy consumption.

With our experience in tackling problems related to high inclines, we supply a specially developed diverse range of Chevron and other profile belts.

The belts have specially been designed with wear resistant covers and cleats to provide a high wear life. The special carcass design enables the frequent flexing these belts undergo in usage.

We offer a wide range of different cleat designs / patterns, depending upon the type of material to be conveyed. The height of the cleat depends upon the lump size of the material to be conveyed and the angle of incline.

These belts are used for Crushers, including mobile for stone aggregate handling, limestone conveying in cement plants, scrap handling, wood chips.

Common Widths : Available in Different Widths of Chevron Belt.

Belt Length range : `L��-160m, `H��-120m

Carcass Variety Available : EP

Common Belt Rating : 200 to 800 KN/M

No. of Plies : 2 ply to 4 ply

Rubber Cover Grades : M24, DIN-X,Y, HAR, SAR, HR, OR; special belts on request

Rubber Covers Thickness : Min. 3.0 mm top and 1.5 mm bottom or Bare back

Rubber : Black

Surface Finish : Cleat on top Covers only

Edge : Cut Edge or Molded Edge

Splicing Method : Hot / Cold splice joint / Mechanical splice

Packing Available in : Palletised Packing

IN A NUTSHELL OUR PRODUCTS ARE FIRST WORLD PRODUCTS AT THIRD WORLD PRICE

- ELECTROCHLORINATORS and ELECTROLYZERS

Sodium Hypochlorite is a powerful biocide and oxidizing agent that has been widely used in seawater cooling system to avoid the biofouling by marine organisms such as barnacles, mollusca, byrozoa, and sponges. They will lodge and grow at sea water intake structures, bar racks and screens, tunnel walls and condenser pipes. It results in reduced seawater flow rate and heat exchanger capability, corrosion of condenser pipes and metallic surfaces in Power plants.

The continuous injection of Sodium Hypochlorite solution at sea water intake with the concentration of 2 to 3 ppm will ensure the complete control of bio fouling.

The Sodium Hypochlorite solution is produced by Electrochlorinators in which Electrolyzers made of MMO ( Mixed Metal Oxide) coated DSA Titanium Anodes and Cathodes are the most important equipment.

We have the expertise for the replacement or refurbishment of electrolyzers and other spares for electrochlorinators, executed by any of the OEMs, namely:

- M/s. Seven Trent De Nora, [Chlortec, Seachlor, Sanilec, Omni pure, Balpure]

- M/s. Siemens, [US Filters, Chloropac, Sanichlor, OSEC, Seapac, Electrocatalytic].

- M/s. Daiki, Japan.

- M/s. Mitsubishi, Japan.

- M/s. Cumberland, UK.

- M/s. Pepcon, USA.

- M/s. Sespi, Italy.

- M/s. Nippon, Japan.

- M/s. Electrichlor, USA.

- M/s. Charles Thompson Limited, UK.

- M/s. Sal-Chlor, Australia.

We also do:

- Site survey and provide solution for enhancing the performance of existing Electrochlorinators

- Design, Supply and Installation of electrolyzers to the OEMs as per their drawing or design

- Operation and Maintenance of the Electrochlorination plant

We are ISO 9000 certified company.

We manufacture Electrochlorinators as per ASME standards.

We use WPS & QAP, approved by M/s. Lloyds, M/s. TUV.

In a nut shell our products and solutions are “First World Products and Solutions at Third World Price��

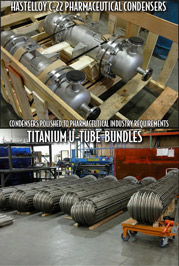

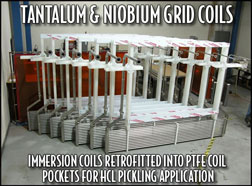

- Any equipment made out of precious materials TITANIUM, TANTALUM, NIOBIUM, ZIRCONIUM, NICKEL, HASTELLOY, MONEL, INCONEL, X-750, PLATINUM, RUTHENIUM, IRIDIUM, PALLADIUM and its alloys

TITANIUM TANTALUM ZIRCONIUM NIOBIUM HASTELLOY etc., PRODUCTS

TITANIUM TANTALUM ZIRCONIUM NIOBIUM HASTELLOY etc., PRODUCTS

We can do designing ,engineering and development and fabrication of any product made out of precious, noble and exotic metals TITANIUM, TANTALUM, NIOBIUM, ZIRCONIUM, NICKEL, HASTELLOY, MONEL, INCONEL, X-750, PLATINUM, RUTHENIUM, IRIDIUM, PALLADIUM and its alloys.

Our Products:

- Heat exchanger, condenser and coils

- Thermowells

- Thermocouple protection sheaths-seamless

- Orifices

- Pumps, pump casings, shafts and impellers

- Distillation columns and boilers

- Tanks, Vessels

- Pipes,Elbows,Tees,Fittings

- Nuts,bolts

Applicable Industries:

Power industries

Electronics industries

Glove making industries

Latex industries

Nuclear industries

Aerospace industries

Chemical industries

Pulp and Paper industries

Fertilizers industries

Defence industries

Petrochemicals industries

Refineries

Metal finishing industries

Anodizing industries

Bio Medical industries

Bio Diesel industries

Our exotic metal products are First World products at Third World Price

- Cathodic protection anodes of any shape

Cathodic Protection Anodes

Cathodic Protection Anodes

ICCP ( Impressed Current Cathodic Protection) is a very popular, effective and proven method of Cathodic Protection implemented for many applications.

We can manufacture any shape of MMO coated titanium anodes, Platinised titanium anodes, Platinised niobium anodes or their copper cored with platinum plated surface which are used in ICCP for injection of protection current to protect the designated object from the harmful corrosion potential.

Different types of ICCP ( Impressed Current Cathodic Protection) Anodes:

- Tubular Anodes

- Tubular String anodes

- Embedded Civil Probe anodes

- Probe anodes

- Rod anodes

- Wire anodes

- Wire anodes (Copper cored)

- Piggyback anodes

- Cantilever anodes

- Canister anodes

- Ribbon anodes

- Strip anodes

- Mesh anodes

- Disc anodes

- Ladder anodes

Applications:

Process Vessels

Reinforced concrete

Water front Structures

Pipe lines

Condenser & Water boxes

Well Casings

Tanks ( Water storage, Under ground, Above ground)

Our ICCP ( Impressed Current Cathodic Protection) Anodes are First World Products at Third World Price

- Alumina Ceramics for Corrosive fluid handling

Industries where corrosive chemicals are handled, very often causes heavy wear of the equipment used, resulting in damage to the equipment, lower reliability, production losses and lower capacity utilisation.

As a Malaysian company representing Carborundum Universal Limited, India, one of the leaders in Industrial Ceramics, we offer alumina ceramics for corrosive fluid handling.

We bring to you Alumina ceramics with 99.5% purity (which are highly corrosion resistant) for various pump mechanical seal applications. Our `t�� type inserts are resistant to highly corrosive acids and alkalis except phosphoric acid and hydrofluoric acids. We can manufacture the seal part to the maximum diameter up to 200mm.

Our shaft protection sleeves are used by major pump manufacturers and every part can be made to customer's individual requirements.

In the transport and control of aggressive fluids, ceramic components provide exceptional resistance to corrosion, mechanical erosion, and abrasion while maintaining their superior surface finish and fit. Ceramic structures of controlled porosity are now finding application in a wide variety of filtration processes.

- Mechanical faces, Rotary unions and faces

- Pump shaft sleeves, linings and plungers

- Valve rim / Meter bearings

- Fine bubble diffusers / Faucet valve plates

- Cryogenic pump components

- Spray nozzles / Compressor components

- Pneumatic and hydraulic control components

- Flow meter components

Ceramic Plungers are the right choice for most saltwater, chemical and metering applications. CUMI's specially formulated grades of ceramic allow a standard 0.8 microns Ra surface finish which extends packing life dramatically.

In a nutshell our products and solutions are First World Products and Solutions at Third World Price

- Ceramic balls for Ceramic Tile Industry

Industries like Ceramic tile Industry where bulk material movement involving sliding, very often causes heavy wear of the equipment used, resulting in damage to the equipment, lower reliability, production losses and lower capacity utilisation.

As a Malaysian company representing Carborundum Universal Limited, India, one of the leaders in Industrial Ceramics, we offer ceramic wear protection solutions for ceramics tile industries.

We supply grinding media and ball mill liners to the ceramics tile industries.

CUMITUFF Grinding Media

The most important requirement for wear resistant ceramic materials are:

- High hardness

- Good resistance to deformation

- Sufficient toughness i.e. resistance against crack formation

and its propagation.

Of all other alumina materials, CUMITUFF fulfils the above requirements excellently

High hardness ensures prolonged resistance to chipping and cracking. Long term benefits are attractive with CUMITUFF media as it is a cost effective alternative to conventional media. Media replacement and make-up charge levels drop significantly with the use of CUMITUFF Alumina Ceramic media.

CUMITUFF Mini - Media

CUMI offers grinding media of size less than 6 mm made by a unique pelletisation process for ultra fine grinding requirements such as in the paint industry. Typical sand mill users can benefit from the use of CUMITUFF Mini-Media by virtue of its non-contaminating characteristics.

CUMITUFF Mill Liners

Using CUMITUFF Mill Liners operating times can be achieved higher than conventional mill linings by 30% depending upon properties of material being ground.

Combination of CUMITUFF grinding media and mill liners will effectively solve your grinding problems.

In a nutshell our products and solutions are First World Products and Solutions at Third World Price.

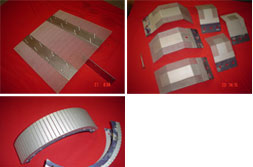

- Ceramic Liners for Steel Industry

Industries like steel Industry where bulk material movement involving sliding, very often causes heavy wear of the equipment used, resulting in damage to the equipment, lower reliability, production losses and lower capacity utilisation.

As a Malaysian company representing Carborundum Universal Limited, India, one of the leaders in Industrial Ceramics, we offer ceramic wear protection solutions for steel industry.

We can design, manufacture, supply and install the wear resistant liners and lined equipment to the steel industry for the following applications:

- Slow Down box & Distributer - INBA SGP

- Rubber Backed Tiles

- Chutes

- Blast Furnace skip car Liners

In a nutshell our products and solutions are First World Products and Solutions at Third World Price

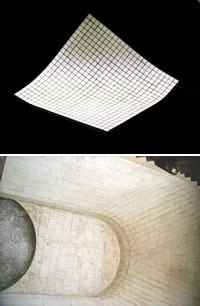

- Ceramic liners for Power Generation Industry

Industries like Power Generation Industry where bulk material movement involving sliding, very often causes heavy wear of the equipment used, resulting in damage to the equipment, lower reliability, production losses and lower capacity utilisation.

As a Malaysian company representing Carborundum Universal Limited, India, one of the leaders in Industrial Ceramics, we offer ceramic wear protection solutions for coal fired power plants.

We can design, manufacture, supply and install the wear resistant liners and lined equipment to the power generation industry for the following applications:

- Ash disposal pipes

- Burner assembly/swing panel/roller bracket assembly

- Fuel inlet elbow -long & short

- Orifices

- Pulverized fuel pipes , Bends, Y-piece, transition piece

- Mill outlet elbow-long and short

- Mill discharge valve

- Multiport outlet

- Classifier top plate

- Distance piece

- Ventury vane

- Inner cone

- Coal mill - Wear inserts

- Blow out nozzle

- Bull ring segment

- Mill body with 25 thick tiles

- Bends and pipes

Our expertise is in manufacturing and supplying pre- engineered wear resistant tiles and ready to fit pre-fabricated lined equipment. We use 3D modelling to ensure a good fit for the contours.

We manufacture weldable and pastable alumina ceramic tiles that can be bonded onto the surface.

Our products offer the following benefits to the power generation industry:

- High wear resistance due to impervious structure

- Superior resistance to corrosion

- Free flow of materials due to good surface finish

- Close fit of ceramic to ceramic /steel ensures improved life of equipment

In a nutshell our products and solutions are First World Products and Solutions at Third World Price

- Ceramic Liners for Coal Washeries

Industries like Power Generation Industry where bulk material movement involving sliding, very often causes heavy wear of the equipment used, resulting in damage to the equipment, lower reliability, production losses and lower capacity utilisation.

As a Malaysian company representing Carborundum Universal Limited, India, one of the leaders in Industrial Ceramics, we offer ceramic wear protection solutions for the coal washeries in coal fired power plants.

We can design, manufacture, supply and install the wear resistant liners and lined equipment for coal washeries for the following applications:

- Hydro-cyclone

- Spigot, nozzles and transitions for hydro-cyclones

- Discharge orifice for solid bowl centrifuge

- Feed orifice for screen bowl centrifuge

- Feed orifice for solid bowl centrifuge

- Ceramic lined Coal Hopper

- Bends for coal conveying

- Y - Piece

In a nutshell our products and solutions are First World Products and Solutions at Third World Price.

- Ceramic liners for Cement Industry

Industries like Cement Industry where bulk material movement involving sliding, very often causes heavy wear of the equipment used, resulting in damage to the equipment, lower reliability, production losses and lower capacity utilisation.

As a Malaysian company representing Carborundum Universal Limited, India, one of the leaders in Industrial Ceramics, we offer ceramic wear protection solutions for cement plants.

We can design, manufacture, supply and install the wear resistant liners and lined equipment to the cement industry for the following applications:

Crusher

- Pulley lagging

- Chutes

Raw mill

- Feed chutes

- Inlet bends and discharge bends

Separator

- Top dome, Louvers, Discharge cones

Cyclones

Gas conditioning towers

- Ceramic nozzles, Screw conveyor casing

ESP ducts

Burner pipe

Packing plant

Bends

Topo gun chutes

Diverting plates

In a nutshell our products and solutions are First World Products and Solutions at Third World Price. - HEA Ignitors

High Energy Arc (HEA) Igniter

The function of a burner is to ignite and burn the fuel by efficiently and completely mixing it with combustion air in the furnace.

Prior to the invention of High Energy Arc Igniter, a pilot burner smaller than the main burner usually ignited by electric spark for a proven ignition energy source required to light off the main oil burner.

High Energy Arc Igniters are now being applied to all new modern burners. These Igniters eliminate the use of pilot gas igniter by directly igniting the oil with low voltage, high amperage spark.

A typical High Energy Arc Igniter system consists of spark rod assembly, spark tip, cable assembly, exciter box, retractor assembly etc.,

High energy can be provided with less weight, lighter wire and greater portability by using a high voltage capacitor-discharge system. A large-value capacitor stores energy during the arming sequence, releasing it in a fraction of a second when it is switched on. To use the energy efficiently, the igniter must be designed for high voltage.

We have developed various igniters for all types of burners. Depending upon the customer requirement, we can supply a suitable High Energy Arc Igniter. Our HEA Igniters are very efficient, light weight, compact design and needs less space.

Exciter:

Exciter:

Input voltage : 110VAC/220VAC

Output Voltage: > 2000 VDC

Stored energy: 12 joules

Spark rate: 4 spark/sec

Duty cycle: 15 sec ON/30sec off

Dimensions (Approximate): Width-150 mm

Height-250 mm

Depth- 250 mm.

Flexible Cable:

Length: 625 mm max

Operating Voltage: 3000 VDC max

Bend Radius: 100 mm min

Construction: PVC coated conduit

Spark Rod:

Length: 3500 mm

Operating voltage: 3000 VDC

Construction: SS tube/ SS flexible hose

Retractor Assembly:

Pneumatic power cylinder: 200 mm stroke

Operating pressure: 70 to 100 psi

Solenoid valve: two position four way solenoid valve

Solenoid operating voltage: 110 VAC /220 VAC

Mechanical Limit switch: 1 form C for close and open positions

Our HEA Igniters are First World Products at Third World Price

- PLATINISED ANODES

Our Platinised Anodes are with platinum coating of any micron thickness and on any shape of substrate material

TITANIUM, TANTALUM ,NIOBIUM ,ZIRCONIUM, MOLYBDENUM ,STAINLES STEEL and also on COPPER

Our Platinised Anodes are used for:

- Electrodialysis

- Electroforming

- Cathodic Protection

- Electrochemical sensing

- Electrowinning

- Refining of metals

- Electrolytic regeneration of Chromic Acid

- Electro plating of Precious metals and base metals

- Electrolytic recovery of precious metals and base metals

- Electrolytic production of Sodium Hypochlorite

- Electro synthesis of Organic chemicals and Inorganic chemicals

Our Platinised anodes can be fabricated of any shape and with any micron thickness of Platinum. Our Platinised anodes are of First World Products at Third World Price.

- TANTALUM PRODUCTS

Our Tantalum Products are ideally suited for reboiling, preheating and condensing of nitric acid, hydrochloric acid, bromic acid, sulphuric acid and combinations of these acids with any other chemicals like aqua regia.

Tantalum has

- High anti corrosion

- High melting point of 5432�� F

- Excellent resistance to most acids at normal temperature

- Excellent resistance to many molten metals sodium, lithium, magnesium, potassium and mercury in temperature up to 2000�� F

Tantalum is widely used in

- Electronics industry

- Nuclear industry

- Aerospace

- Chemical industry for application such as vacuum furnace where heat transfer through acids, corrosive fluid and vapour is required

Our Tantalum products are such as

- Bayonet heater, heat exchanger, condenser and coils

- Thermocouple protection sheaths-seamless

- Pump casings, shafts and impellers

- Distillation columns and boilers

- Evaporation boats

- Clad dip pipes and heaters

- Paddle stirrers and agitators

- Furnace parts for use at temperature up to 2500�� C

- Repair kits for tanks, vats and glass lined reactors

Tantalum material used by us confirming to ANSI/ASTM B708 and 365,Gr R05200

Our Tantalum products are First World Products at Third World Price.

- Grounding Probes and Flanges for Electrolysers

GROUNDING_EARTHING PROBES AND RINGS _INSULATED FLANGES FOR ELECTROCHLORINATORS AND ITS ELECTRO MAGNETIC FLOW METERS

GROUNDING_EARTHING PROBES AND RINGS _INSULATED FLANGES FOR ELECTROCHLORINATORS AND ITS ELECTRO MAGNETIC FLOW METERS

Sodium Hypochlorite is a powerful biocide and oxidizing agent that has been widely used in seawater cooling system to avoid the biofouling by marine organisms such as barnacles, mollusca, byrozoa, and sponges. They will lodge and grow at sea water intake structures, bar racks and screens, tunnel walls and condenser pipes. It results in reduced seawater flow rate and heat exchanger capability, corrosion of condenser pipes and metallic surfaces in Power plants.

The continuous injection of Sodium Hypochlorite solution at sea water intake with the concentration of 2 to 3 ppm will ensure the complete control of bio fouling.

The Sodium Hypochlorite solution is produced by Electrochlorinators in which Electrolyzers made of MMO ( Mixed Metal Oxide) coated DSA Titanium Anodes and Cathodes are the most important equipment.

We have the expertise for the replacement or refurbishment of electrolyzers executed by any of the OEMs, namely

- M/s. Seven Trent De Nora, USA

[Chlortec, Seachlor, Sanilec, Omni pure, Balpure]

- M/s. Siemens, USA

[US Filters, Chloropac, Sanichlor, OSEC, Seapac, Electrocatalytic].

- M/s. Daiki, Japan.

- M/s. Mitsubishi, Japan.

- M/s. Cumberland, UK.

- M/s. Pepcon, USA.

- M/s. Sespi, Italy.

- M/s. Nippon, Japan.

- M/s. Electrichlor, USA.

- M/s. Charles Thompson Limited, UK.

- M/s. Sal-Chlor, Australia.

We are ISO 9000 certified company.

We manufacture Electrochlorinators and its spares as per ASME standards.

We use WPS & QAP, approved by M/s. Lloyds, M/s. TUV

We can fabricate Grounding probes of any shape for any type of Electrolysers, Grounding rings of any shape for the Electromagnetic flow meters. These Grounding probes and rings are coated with MMO coating.

We can also fabricate Electrode cell and its insulated end flanges

In a nut shell our products and solutions are “First World Products and Solutions at Third World Price��

- TITANIUM PUMPS

We can fabricate pumps out of exotic metals Titanium, Tantalum, Ti-Pd, Zirconium, Nickel, Hastelloy, Inconel, Monel and Alloy-20

Our pumps are ideally suited for chemical process applications where nitric acid, hydrochloric acid, bromic acid, sulphuric acid and combinations of these acids with any other chemicals like aqua regia or corrosive chemicals handling are used.

One of the Exotic metals Titanium has:

- Superior corrosion resistance

- High melting point of 3020�� F

- Continuous service temperature can reach upto 800�� F

- Occasional intermittent service can reach upto 1000�� F

Another novel Exotic metal Tantalum has:

- High anti corrosion

- High melting point of 5432�� F

- Excellent resistance to most acids at normal temperature

- Excellent resistance to many molten metals sodium, lithium, magnesium, potassium and mercury in temperature up to 2000�� F

We can fabricate pumps to the following specifications:

- Discharge capacity: up to 2000 m3/hr

- Head: up to 200 mtrs

- Variable Speed: 1440/2900 rpm

- Operating pressure: 52 kg/cm2 max

- Temperature: up to 400�� C

Our pumps have the following features:

- Durable and versatile to various chemical process

- Back pullout design

- Novel and simple construction using Exotic metals

Our pumps are fabricated according to standards API 610, ISO 2858 and tested according to standards API 610, IS 5120

Our pumps made out of Exotic metals are First World Products at Third World Price.

- Oil Free Compressors

Normally in an oil-free compressor, the air is compressed entirely through the action of the screws, without the assistance of an oil seal and that too on multi stage. But, our oil –free compressors are piston type and that too Single stage.

Oil-free compressors are used in applications where entrained oil carry-over is not acceptable, such as

Medical research,

Semiconductor manufacturing,

Oxygen generators,

N2 generators,

Telecom cable pressurisation & short wave guide systems,

Small pneumatic actuator systems,

Inflatable door seals,

Dental and medical air tools

Jewellery makers.

Our Oil-free air compressors can be mounted in any orientation as long as anti-vibration mounts are used to stop vibration, this reduces bearing wear on the motor bearings

Compact Piston

Piston and piston rod form a single rigid unit. By using this type of construction there develops beside the lifting action a tilting motion. To compensate for this the compact piston is fitted with a special seal element.

High Quality Valves

Lamellar valves made of high-grade spring steel ensure a constant performance.

Robust Bearings

Manufactured to the highest tolerances and sealed for life, completely maintenance free ball bearings with double RS seal.

Cooling System

Two fans built into the motor and crankcase produce a high level of cooling air, maintaining a low running temperature creating the condition for 100% continuous operation at 7-bar pressure. Even with an ambient temperature up to 40 °C.

Salient Features of our compressors:

- Economical, small and compact design

- High reliability

- Pleasantly Low noise levels

- Plug and play straight from the box

- High reliability

- Extremely long service life

- Low noise levels

- 100% continuous operation for thousands of non stop operating hours

Available for maximum Nominal Pressure of 7 bar and Safety pressure of 10bar

Extensive range of accessories

We can offer:

We can supply oil free compressors of highest standards for any applications. We have readily made compressors of various capacity and we can also Engineer and supply according to the customer’s requirement.

Compressors for various different voltage levels, frequencies and also DC voltage.

Different protection classes on request.

Sound-pressure level measured according to ISO 2151 and ISO 3744.

Free air Flow at 0 bar 25 ,30 ,38 ,40,65,75,130,150 and 73LPM

Motor power rating 570,640,660,650,560,1040,1060,900,1170,

1100,990,310,290,192, 240,270,220,122 and 156W

Motor current rating 1.5,1.17-0.68,17.5,

2.1,1.2,0.55,6.4,13,2.5,2.8,5.8,1.3,1.1,4.6,2.0,4.3,10.2,1.9,2.2A

Motor voltage rating 110/115V,230V,400V AC; 24V,12V DC

Protection class IP20, IP54

Noise level 55,57,59,60,67,64,70 and 61dB(A)

Pressure receiver volume 3 litres and 10 litres

Weight 11kg and 17kg

Dimensions

330x330x320mm,545x180x400mm,230x151x158mm,233x129x158mm,209x108x156mm,

252x165x180mm,242x121x175mm,280x167x218,305x190x218mm,308x190x218mm, 260x167x218mm,367x167x218mm,318x167x218mm,340x276x190mm,297x276x190mm,323x276x190mm

- Sarificial Anodes

Cathodic protection is an electrochemical process which halts the corrosion (natural reaction) of metals in a particular environment, by superimposing an electrochemical cell more powerful than the corrosion cell.

Sacrificial Anodes are fitted or bonded to the metal to be protected which in turn, as it has a greater electrical potential than the anode material, becomes cathodic and causes the anode to sacrifice itself.

In a correctly installed Cathodic Protection System the only corrosion occurs to the sacrificial anode which is replaceable. The number and size of anodes is determined by the type of material and the surface area being protected.

In a simpler explanation we can say that an anode attached to a metal object, such as a boat or underground tank, inhibits the object's corrosion. The anode is electrolytically decomposed while the object remains free of damage.

We can manufacture and supply die cast zinc, aluminum, and magnesium sacrificial anodes which provide low cost cathodic protection of ocean-going vessels, structures and equipment constructed of iron, steel, aluminum, magnesium, and other metals.

We can manufacture different type of anodes, as below, according to the application:

Zinc Alloy (US Mil-A-18001K): For Salt Water Only

Aluminum Alloy (US MIL-A-24779(SH): For Salt & Brackish Water Only

Magnesium Alloy (AZ91D): For Fresh Water Only

Hull Anodes

Olympic Drive Anodes

Heat Exchanger Anodes

Heater Treater Anodes

Platform Standoff Anodes

Cable Anodes

Ballast Tank Anodes

Condenser Anodes

Crab Trap Anodes

Propnut Anodes

Plate Anodes

Rod Anodes

Our anodes are pressure diecast and manufactured to strict quality standards through an ISO 9001 Quality Management System.

In addition, each alloy is guaranteed to be manufactured to the latest US

Military Alloy Specification and is chemically tested regularly in our in-house labs to ensure consistency.

Poorly manufactured anodes may contain high levels of impurities such as iron, which might leave your asset unprotected.

- Air Operated Double Diaphragm Pumps

Air Operated Double Diaphragm Pumps made of Polypropylene (PP) and Polyvinylidene Fluoride (PVDF), Stainless Steel, Aluminium, Cast Iron

Air Operated Double Diaphragm Pump (AODD) is double pumps in one, with two chambers filled and emptied by drawing liquid through a common inlet and discharged through a common outlet. The diaphragm in each chamber is connected by a common shaft so that they move backwards and forwards together. Compressed air is directed by the air valve alternatively behind each diaphragm to power discharge strokes. Pump speed and there fore fluid flow rate can be infinitely controlled by increasing or decreasing air pressure and or volume.

Standard AODD pumps are 1:1 ratio so that maximum outlet pressure never exceed air supply pressure.

Typical range of process liquids where AODD can be used:

Abrasives like Clay slip, titanium dioxide; All mineral and organic acids; Cement and Mortar; Cosmetics like Creams, emulsions, detergents; Ceramics like Slip glazes and clay; Mud, grout and lubricants from Drilling Operation; Soft drinks, spirits, beer, wine, milk, Inks and Dyes like printing inks, driers, dyes, sixes and solvents; Liquid and semi solid foods, flavourings; Oils like Petrol, diesel, hydraulic and cutting oils, lube oils , animal and vegetable oils and greases.; Pulps like paper ,wood ; Resins like Natural and synthetics, water and solvent based, monomeric and polymeric plastics; Sludge and waste like sewage, effluents, coal and lime slurry; Solvents like Aromatic and aliphatics, ketones, aldehydes, esters and chlorinated hydrocarbons, de icing fluids; Water of all types; Timber preservatives like creosote, turpentine, copper napthenate; Paint like emulsions, latexes, pigments, solvents, resins, thinners; Phramaceuticals in liquid, creams and compounds form; Plating industry liquids like Aggressive acids,salts, sludge and effluents; Rubber of Natural and Synthetic form.

Advantages of AODD pumps:

- No seal, No leakage,No motor,No fire,No rotation,No charging.

- Less wear and tear, Self priming, No foot valve needed, Pump can run dry.

- Variable flow with the same pump, Stop automatic on closing of discharge valve.

- Light weight,handy in use ,can be submerged easily.

- Less stock of spare parts. No skilled person needed to operate or repair the pump.

- Can also be used as metering pump with accuracy upto 3-5%.

In a nutshell it is very simple and versatile pump as a First World Product at Third World Price.

- Drum or Barrel Pumps

Drum pumps for Low Viscous Liquids:

Drum pumps for Low Viscous Liquids:

In these Drum Pumps, a pump tube is connected to motor by means of self aligning coupling. The motor transmits power through coupling to the drive shaft of pump which is well supported by TEFLON Bearing. The impeller is mounted at the foot piece of the pump tube and is always immersed in the liquid which assures self priming.

The Drum Pump empties the drum to residue of 1 Liter Self Priming and also self draining on completion. No welding is involved in any part of pump tubes. Complete strip down is possible with least number of tools.

Drum Pump with Electric Motor

Fully enclosed, fan cooled motors with ON/OFF switch, Single phase AC or DC, Intermittent duty related with 15 feet long industrial cord and plug

Drum Pump with Pneumatic or Air Motor

Variable speed drive with in built control valve. Suitable for safe operation in flammable environments. Automatically cools down due to expansion of compressed air. Air requirement is 18cfm at 3- 6 bar. Air inlet size ¼��.

As sparking or fusing is not possible, Air Motor offers explosion protection without any additional cost.

Drum pumps for High Viscous Liquids:

This type of Drum Pumps are designed as progressing Cavity Type Screw Pumps for pumping medium to high viscous liquids. The progressing cavity design ensures smooth and non pulsating flow and ideal for the gentle transfer of liquids.

Pumping action starts the moment the Rotor turns. Liquid enters the pump suction under pressure as the Rotor turns within the Stator, thus forming tightly sealed cavities which moves the liquid towards the outlet .Moreover the liquid acts as a lubricant between Rotor and Stator.

Features:

- Available in SS316 / 304 material.

- Maximum flow rate of 60kg/min with a discharge pressure up to 8bar.

- Can generate differential head up to 80meters for low viscous liquids.

- The flow rate is approximately proportional to the speed.

- However, pumping pressure does not depend upon the speed.

- Rotor is made of SS316.

- Stator is made of metal tube with internally molded synthetic rubber or Viton or Butyl or Neoprene or EPDM or Nitrile or Teflon

Applications:

Suitable for highly viscous liquids such as Molasses, Syrups, Liquid Chocolate, Honey, Glycerin, Liquid Soap, Plastic Solutions, Resins, Glues, Shampoos, Grease, Wax etc.,

In a nutshell it is very simple pump as a First World Product at Third World Price.

- Peristaltic Transfer or Hose or Tube Pumps

Our Peristaltic Transfer or Hose or Tube Pumps are available in three different series to suit the different customer requirements.

Operating Principle:

Two or three rotating rollers gradually compress a tube forcing liquid through the tube just ahead of each roller The tube returns to its original shape after rollers pass so it can fill with more liquid again.

Peristaltic pumps for pumping small volumes and for accurate metering:

Flow rate: 28 LPH to 6400LPH

Pressure: 8 to 15bar

Tube Diameter:10 ��16 �� 26mm

One or two heads

Fitted with Pulse dampener

Peristaltic pumps for pumping medium volumes:

Flow rate: 3000 LPH to 18000 LPH

Pressure: 8 to 15bar

Tube Diameter:40 ��55 �� 68mm

One or two heads

Fitted with Pulse dampener

Fitted with Inlet hopper.

Peristaltic pumps for pumping high flow:

Flow rate: 10000 LPH to 60000 LPH

Pressure: 8 to 15bar

Tube Diameter:76mm

One or two heads

Fitted with Pulse dampener

Fitted with Inlet hopper.

Advantages:

No seal, No valves, Self priming, Pump can run dry.

Pumped fluid always remains inside the tube, Time saving in C.I.P applications.

Reverse flow by reversing motor, Pump mixed phases, Minimum shear.

Applications:

Fragile and sensitive fluids: Emulsions, fruit salads, sparkling wines, tomatoes, purees, dairy products, antifoaming agents, whole grapes, fruit juices.

Compound fluids: Butchery waste, additive metering, paper pulp, grape marc, animal feeds, minced fruit, polymers, sugar beet and potato processing waste.

Abrasive and corrosive fluids: Bentonite, mud and sediment, enamels, pigments, lime wash, casting slip, plaster mortar, concrete, fertilizers, manure slurry.

Non-pollutable or pollutant fluids: Rubber latex, food products.

In a nutshell it is very simple and versatile pump as a First World Product at Third World Price.

- Polypropylene (PP) Centrifugal Pumps

Polypropylene (PP)

Polypropylene (PP), also known as polypropene, is a thermoplastic polymer used in a wide variety of applications. it is rugged and unusually resistant to many chemical solvents, bases and acids. Polypropylene is normally tough and flexible, Polypropylene has good resistance to fatigue.

We manufacture Polypropylene Centrifugal Pumps of following type as solution to corrosive fluids:

Monoblock Polypropylene Pumps

Bare shaft Polypropylene Pumps

Vertical Chemical Pump with Shaft assembly

Sealless and glandless vertical Polypropylene Pumps

Specifications:

Capacity up to 126m3/hr

Head up to 35 meters

Power up to 25HP

Applicable process fluids and Industries:

Concentrated HCl

Scrubbing of corrosive gases like Cl2,Br2,F2,I2,SO3,CO3,NH3

Water Treatment

Effluent Treatment

Electroplating

Pickling in Steel Rolling Mills

Caustic Soda Plants

Dyes and Chemicals

Drugs and Pharmaceuticals

Fertiliser Plants

Power Plants

Steel Plants

Paper and Pulp Industries

Rayon and staple Fibre Plant

Copper ,Zinc Smelter

TiO2 Plant

Salient Features:

All pumps, shaft are available with sleeves of different materials compatible with the liquid handled.

All pumps are available with externally mounted balanced mechanical seal or Teflon Gland Packing or internal mechanical seal with elastomer bellows.

Ploypropylene Volute and impellers are injection moulded which provide smooth hydraulic passage.

Injection moulded Polypropylene components provides higher strength Higher efficiency and better surface finish.

In a nutshell it is very simple and versatile pump as a First World Product at Third World Price.

- Portable Submersible Sewage Pumps

Our Portable Submersible Sewage Pumps are made of Investment Casted SS316 Components

Specification:

Capacity Range : 25LPM to 2400LPM

Head Range : Up to 30meter

Electrical Motor : 0.5HP to 10HP

Sealing Arrangement : Double Mechanical Seal

Carbon vs Ceramic on motor side

SiC vs Steel on pump side

Salient Features:

- Submersible.

- Non clog impeller to handle solids ( up to 35mm solids without strainer).

- Double mechanical seal.

- With float switch to protect against dry run, auto start and stop.

- All parts in SS316.

- Float also available with 3 phase.

Motor:

Available in single phase and three phase squirrel cage induction dry motor

with class “F�� insulation and IP68 protection.

Application:

Sewage Water

Septic tank

Effluent Treatment

Waste Water

Dirty water

In a nutshell it is a very simple pump as a First World Product at Third World Price.

- Sealless Magnetic Driven Pumps

Our Sealless Magnetic Driven Pumps do not have conventional mechanical seals as pump chamber is shielded by casing and impeller is operated by magnets. Hence these pumps are totally leak proof. These sealless pumps are ideal for transfer of chemicals like acids etc., since they are leak proof and made from polypropylene, totally eliminating contamination of liquid transferred.

Specification:

Capacity range : 5LPM to 500LPM.

Head range : Up to 1 Meter.

Electrical Motor : Up to 5 HP.

Sealing arrangement: No seal.

Front casing, Rear Casing & Impeller are in glass filled polypropylene / PVDF / SS. Shaft is made of ceramic & guided in carbon filled Teflon bush.

Typical range of process liquids where these pumps can be

used:

AMM, Chloride, Cupric Cyanide, Ethanol, Ferrous, Sulphate, Potassium Di- Chromate, Sodium Chloride, Petrol, Kerosene, milk, alcohol and many more.

Applicable Industries and process:

Chemical, Pharmaceutical, Textile Processing / Dye Baths, Electroplating, Metal finishing, Filtration, General Laboratories, Ultrasonic Cleaners, Water Treatment Plants, Galvanizing/ Anodizing / Plating plants, Pure water Plants, Boilers, Heat Exchangers, Domestic Aquariums, X- Ray Film Processors, Medical Equipment, Colour Photo processors, Silver Recovery Systems, Solar Heating Systems, Coolant Pumping Equipment on Machine tools/ Metal working Machines, TV Tube Processing, IC Photoengraving Processing ,PCB Plants, Display Devices, Etching Machines , Spark Erosion Machines , Gas Analysers, Coolant Pumping for Laser Systems

In a nutshell it is very simple and versatile pump as a First World Product at Third World Price.

- Self Priming Stainless Steel (SS) Pumps

Our Self Priming Pumps with its Volute Casing, Open Turbine type impeller & back plate is made from SS-316 Investment casting.

Specification:

Impeller: MOPL

Capacity range : 7LPM to 125LPM.

Head range : 2 to 30Meter.

Electrical Motor : 0.5HP to 2.0 HP.

Sealing arrangement : Ceramic & Graphite with Vitlon or Teflon Elastomer.

Salient Features:

Typical range of process liquids where these pumps can be used:

Barium Cyanide, Barium Sulphate, Carbon Di Sulphate, Hexane, Hydrogen Fluoride Platting Sol, Copper & Iron and many more.

Applicable Industries and process:

Wide range of application in various industries such as alimentary, petro- chemical, Textile, Pharmaceutical, Depuration. For pumping inflammable liquids with flame proof motors.

Specification:

Impeller : MOEL

Capacity range : 5LPM to 270LPM.

Head range : 2 to 18Meter.

Electrical Motor : 0.5HP to 2.0 HP.

Sealing arrangement: Carbon vs Ceramic

Salient Features:

This pump can handle soft solids, small cloth particles.

Typical range of process liquids where these pumps can be used:

Butter, Butter Milk, Fatty Acid, Hydrogen Sulphate ,Polluted Water and many more.

Applicable Industries and process:

Ideal solution to pumping problems in depuration plants with polluted water, for textile industries, food, petrochemicals and Galvanize industries..

In a nutshell it is very simple and versatile pump as a First World Product at Third World Price.

- Blowers- Axial and Centrifugal Fans

VJIKKS ENGG POWER (M) SDN BHD

VJIKKS ENGG POWER (M) SDN BHD offers Single inlet Single width/ Double inlet Double Width fans from capacity 60M3/Hr to 250000 M3/Hr with pressure range from 60 mmwg to 1500 mmwg for single inlet single width and 1000 mmwg to 2000 mmwg for multi stage fan to suit customer duty conditions at optimum efficiency to satisfy industrial needs.

We offer wider range of material of construction like mild steel, SS304/SS316, PP/FRP, MS with rubber lining and can be coated with special corrosion-resistant paint, epoxy, heat resistant paints.

Applications

Water Treatment Plants

Chemical Processing Plants

Boilers al Foundries

Sugar Factories

Textile Industries

Ventilation / Humification

Sewage Treatment Plants

Industrial Furnaces

Dairy Industry

Cement Factories

Glass Factories

Pneumatic Conveying System

To get correct offer please furnish the following details:

- Capacity or volume …………CFM or m³/hr

- Static pressure at working Temp ……….MMWG / INCHWG

- Air or Gas Temp ……….°C

- Application ………..

- Dust loading ………. (mg/nm³)

- Drive type ………… Vbelt / coupling

- Fan orientation from the following chart - ………..

In a nutshell our Blowers and Centrifugal and Axial Fans are First World Products at Third World Price

|

| Our Solutions |

| |

Reduction of water consumption Reduction of water consumption

|

| Close details |

| Reduction of water consumption |

| Are you paying heftily for your plant process water consumption? |

| Do you want to get the water consumption reduced? |

| “We can help you�� |

|

| |

Fact Finding on Air Cooled Generators Fact Finding on Air Cooled Generators

|

| Close details |

| Fact Finding on Air Cooled Generators |

| Do you want to get the Fact Finding inspection done by 25 years Power Plant experienced personnel? |

| Do you want to know the symptoms of rotor winding fault? |

| “We can find for you�� |

|

| |

|

Electrochlorination Plant Operation and Maintenance Electrochlorination Plant Operation and Maintenance

|

| Close details |

| Electrochlorination Plant Operation and Maintenance |

| Do you want to know how to prolong the designed life of the Electrolysers? |

| Do you want to know how to easily identify the Electrolyser approaching its life time? |

|

| |

Batteries Maintenance Batteries Maintenance

|

| Close details |

| Batteries Maintenance |

| Do you want to know how to identify the individual weak cells in a battery bank? |

| Do you want to know how to escape from the replacement of the entire battery bank ? |

| Do you want to know how not to get carried away by the manufacturers? |

|

| |

EHV, HV Switch gear Maintenance EHV, HV Switch gear Maintenance

|

| Close details |

| EHV, HV Switch gear Maintenance |

| Do you want to know the well tried and well tested maintenance practice? |

|

| |

Engineering Procedures for Testing, Commissioning and Maintenance Engineering Procedures for Testing, Commissioning and Maintenance

|

| Close details |